RPh_Guy

Bringing Sour Back

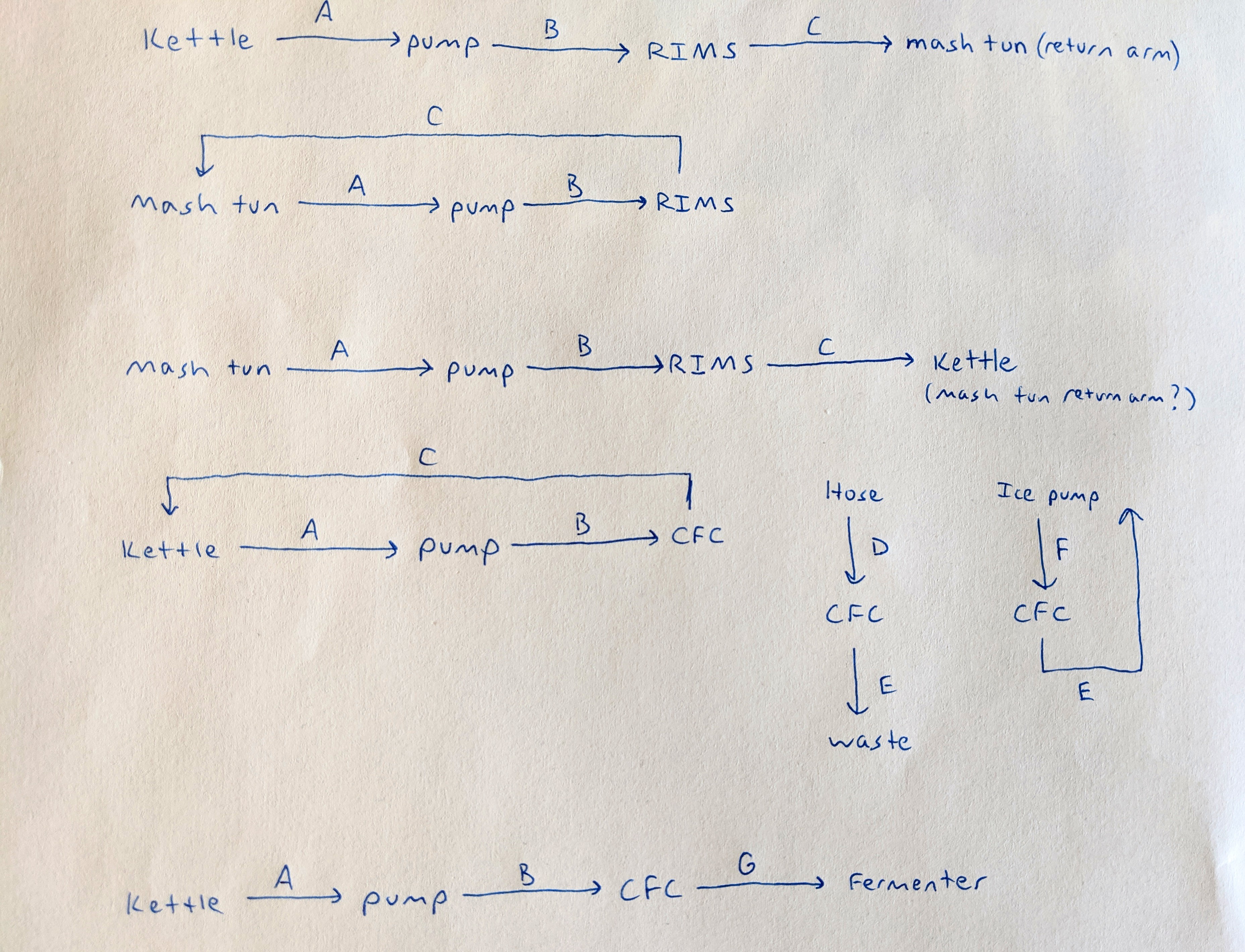

I mash in a 10 gal cooler and I'm purchasing a RIMS package from brewhardware.

I'm using a floating stainless pizza pan as the mash cap. There's only about 3/4" clearance between the mash cap and the wall of the cooler.

I'm wondering what's the best way to set up the wort return to avoid aeration and also avoid wrecking the grain bed?

It needs to drop about 5-8" into the mash tun for my regular size batches.

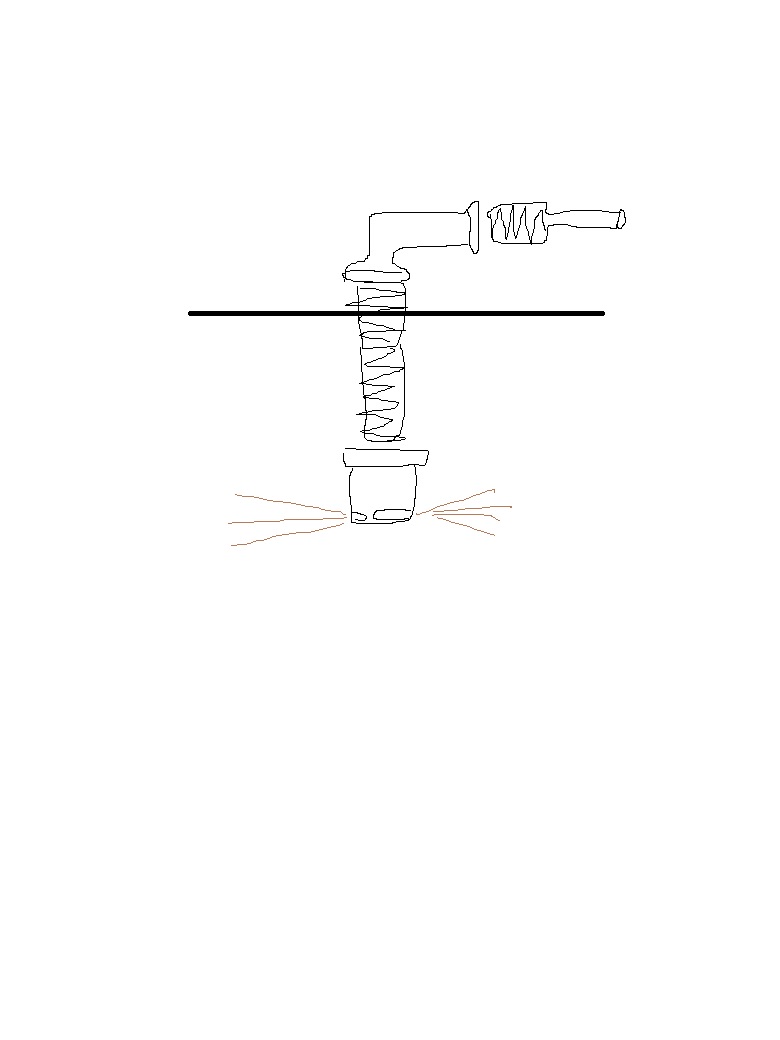

Some kind of Loc-Line with an elbow to direct the incoming wort sideways?

A couple elbows top so it can just rest on the rim of the cooler/tun?

I'm using a floating stainless pizza pan as the mash cap. There's only about 3/4" clearance between the mash cap and the wall of the cooler.

I'm wondering what's the best way to set up the wort return to avoid aeration and also avoid wrecking the grain bed?

It needs to drop about 5-8" into the mash tun for my regular size batches.

Some kind of Loc-Line with an elbow to direct the incoming wort sideways?

A couple elbows top so it can just rest on the rim of the cooler/tun?